Best Weather Stripping for Outside Doors: Complete Guide

Are you tired of drafty doors that let cold air sneak into your home? Your energy bills are climbing, and your comfort is suffering. The right weather stripping can transform your home’s efficiency overnight.

The best weather stripping for outside doors includes foam tape, V-strip, door sweeps, and rubber gaskets, each designed for specific door types and gap sizes. Professional-grade materials like EPDM rubber and silicone provide superior durability and sealing performance.

This comprehensive guide reveals the top weather stripping solutions that professional contractors trust. You’ll discover which materials work best for your specific door type and climate. Get ready to slash your energy costs and enjoy year-round comfort.

Key Takeaways

- Choose the Right Material for Your Climate: EPDM rubber and silicone weather stripping perform best in extreme temperatures, while foam tape works well for moderate climates. Cold regions need flexible materials that won’t crack, and hot climates require UV-resistant options that won’t degrade under intense sunlight.

- Proper Installation Saves Money Long-Term: Quality weather stripping reduces energy costs by 10-20% when installed correctly. The investment typically pays for itself within two years through reduced heating and cooling bills, making it one of the most cost-effective home improvements available.

- Different Door Areas Need Different Solutions: Door sweeps seal bottom gaps, V-strips work best for sides and tops, while compression gaskets provide premium sealing for high-traffic doors. Each area requires specific materials designed for its unique sealing challenges and operational stresses.

- Surface Preparation Determines Success: Clean, dry surfaces are essential for proper adhesive bonding and long-term performance. Remove old residue, sand rough areas, and ensure surfaces are completely dry before installation to prevent premature failure.

- Regular Maintenance Extends Service Life: Inspect weather stripping twice yearly during spring and fall maintenance periods. Look for compressed foam, cracked rubber, or visible daylight around closed doors. Address minor issues promptly to prevent progressive deterioration.

- Professional Installation Benefits Complex Projects: DIY works well for basic foam tape applications, but complex gasket systems or door modifications require professional expertise. Professional installation ensures proper fit, maintains warranties, and delivers optimal long-term performance.

- Measure Gaps Accurately for Best Results: Use feeler gauges to measure actual gap dimensions at multiple points around door perimeters. Select materials 25-50% thicker than measured gaps to ensure adequate compression for effective sealing when doors close.

Weather Stripping Basics

Weather stripping serves as your home’s first line of defense against air infiltration. This essential barrier prevents conditioned air from escaping while keeping outdoor elements at bay. Quality weather stripping can reduce energy loss by up to 30 percent in typical homes.

The primary function involves creating an airtight seal around door frames and moving parts. When doors close, the weather stripping compresses to fill gaps and cracks. This compression creates a continuous barrier that blocks air movement in both directions.

Types of Air Leaks Around Doors

Door frames naturally develop gaps over time due to settling and wear. The most common leak points include the door jamb sides, where the door meets the frame vertically. These areas often show visible light when doors are closed.

Bottom gaps represent another major source of energy loss. Most exterior doors have space beneath them for clearance over thresholds. Without proper sealing, this gap allows significant air exchange between indoor and outdoor environments.

Top headers frequently get overlooked during weather stripping projects. However, warm air naturally rises and escapes through these upper gaps. Addressing header leaks provides substantial energy savings in heating climates.

Climate Considerations

Different climates demand specific weather stripping characteristics. Cold climates require materials that remain flexible at low temperatures. Rubber compounds and silicone perform well in freezing conditions without becoming brittle.

Hot climates need UV-resistant materials that won’t degrade under intense sunlight. Vinyl and specially formulated rubber compounds maintain their sealing properties despite temperature extremes. Heat expansion also affects gap sizes throughout the day.

Humid environments present unique challenges for weather stripping longevity. Moisture can cause certain materials to swell, shrink, or develop mold. Closed-cell foam and synthetic rubber resist moisture absorption better than natural materials.

Top Weather Stripping Materials

Foam Tape Weather Stripping

Foam tape represents the most user-friendly option for DIY installations. This self-adhesive material comes in various thicknesses to accommodate different gap sizes. The closed-cell structure provides excellent insulation while resisting moisture absorption.

Installation simplicity makes foam tape ideal for beginners. Simply clean the surface, measure the required length, and apply the adhesive backing. The material compresses easily when doors close, creating an effective seal.

However, foam tape has limited durability compared to other options. High-traffic doors may compress the foam permanently over time. Replacement typically becomes necessary every two to three years depending on usage patterns.

V-Strip Weather Stripping

V-strip weather stripping offers superior longevity and performance for exterior doors. The V-shaped profile creates two sealing surfaces that adapt to irregular gaps. This design maintains effectiveness even as door frames shift slightly over time.

Metal V-strips provide the longest service life, often lasting decades with proper installation. Bronze and stainless steel options resist corrosion while maintaining their spring tension. The material flexes repeatedly without losing its sealing ability.

Vinyl V-strips offer a more affordable alternative with good performance characteristics. These strips install easily and provide reliable sealing for moderate climates. However, extreme temperatures may affect their flexibility over time.

Door Sweeps and Thresholds

Door sweeps attach to the bottom of doors to seal the gap above thresholds. These devices feature a flexible sealing element that drags across the threshold surface. Quality sweeps adjust to accommodate slight irregularities in floor surfaces.

Brush sweeps use dense bristles to create a flexible barrier. The bristles conform to textured surfaces while allowing easy door operation. This design works particularly well for doors that open over carpeted areas.

Rubber blade sweeps provide more aggressive sealing for smooth surfaces. The continuous rubber edge creates an airtight barrier when properly adjusted. These sweeps handle larger gaps better than brush-style alternatives.

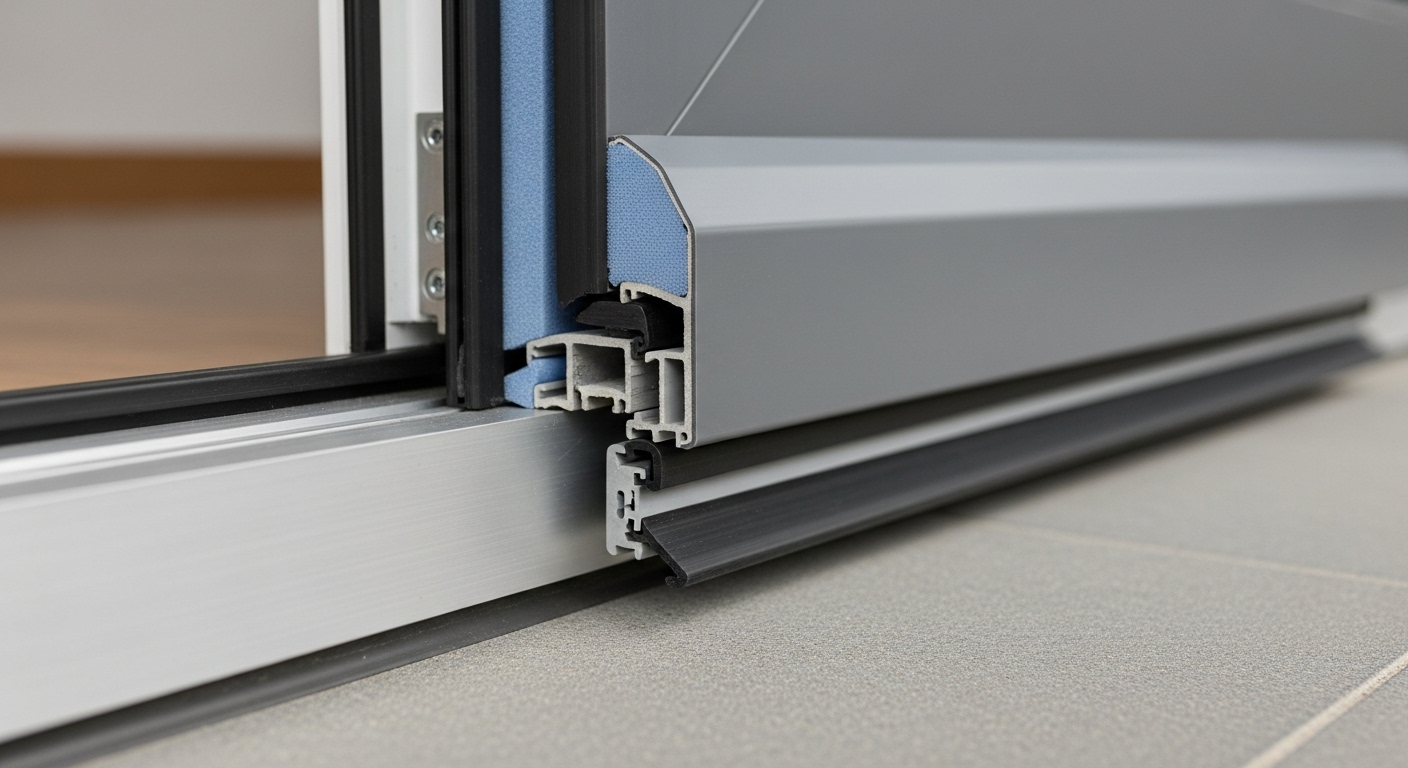

Rubber Gasket Systems

Compression gaskets represent the premium solution for exterior door sealing. These systems use specially shaped rubber profiles that compress when doors close. The compression creates a weatherproof seal that handles extreme conditions.

Bulb gaskets feature a rounded profile that compresses evenly across the sealing surface. This design distributes pressure uniformly, preventing premature wear. The bulb shape also helps the gasket return to its original form after compression.

Kerf gaskets insert into grooves cut into door frames. This installation method provides a clean appearance while ensuring proper alignment. The gasket material extends beyond the frame surface to contact the door when closed.

Installation Methods and Techniques

Surface Preparation

Proper surface preparation determines weather stripping longevity and effectiveness. Begin by thoroughly cleaning all surfaces where weather stripping will attach. Remove old adhesive residue, paint chips, and accumulated dirt using appropriate solvents.

Surface smoothness affects adhesive bonding and sealing performance. Sand rough areas lightly to create a uniform surface. Fill significant gaps or holes with appropriate filler materials before proceeding with installation.

Moisture content must be minimal for successful adhesive bonding. Allow surfaces to dry completely after cleaning. Avoid installation during humid conditions or when surfaces feel damp to the touch.

Measuring and Cutting

Accurate measurements prevent waste and ensure proper coverage. Measure each door opening section separately, as dimensions often vary slightly. Add a small overlap allowance for materials that require joining at corners.

Cutting techniques vary by material type and required precision. Use sharp utility knives for foam materials, making clean cuts without tearing. Metal materials may require tin snips or specialized cutting tools for clean edges.

Corner treatments require special attention for continuous sealing. Miter cuts at 45-degree angles provide the best appearance and sealing performance. Some materials benefit from corner pieces designed specifically for these applications.

Adhesive vs. Mechanical Fastening

Adhesive installation offers convenience and clean appearance for many weather stripping types. Modern adhesives provide strong bonding when applied to properly prepared surfaces. However, adhesive-only installations may fail in extreme temperature conditions.

Mechanical fastening provides superior holding power for high-stress applications. Screws, nails, or staples create permanent attachment that withstands door operation forces. This method works particularly well for door sweeps and heavy-duty gaskets.

Combination methods use both adhesive and mechanical fasteners for maximum security. The adhesive provides immediate bonding while fasteners ensure long-term attachment. This approach works well for critical sealing applications.

Maintenance and Replacement

Inspection Schedule

Regular inspections help identify weather stripping problems before they affect comfort or energy efficiency. Check all exterior door sealing systems at least twice yearly, preferably during spring and fall maintenance periods.

Visual indicators of weather stripping failure include compressed foam, cracked rubber, or detached sections. Look for daylight visible around closed doors, which indicates gap formation. Physical damage from door operation also signals replacement needs.

Performance testing involves checking for air movement around sealed doors. Hold a lit candle or tissue paper near door edges on windy days. Flickering flames or moving paper indicate air leaks requiring attention.

Cleaning Procedures

Gentle cleaning extends weather stripping service life significantly. Use mild soap solutions and soft brushes to remove accumulated dirt and debris. Avoid harsh chemicals that may degrade rubber or vinyl materials.

Lubrication needs vary by weather stripping type and installation method. Moving parts like door sweeps benefit from occasional lubrication with appropriate products. Avoid petroleum-based lubricants that may damage rubber components.

Seasonal maintenance includes removing ice buildup and checking for damage from extreme weather. Clear drainage channels around thresholds to prevent water accumulation. Address minor damage promptly to prevent progressive deterioration.

Replacement Indicators

Compression set occurs when foam materials lose their ability to return to original thickness. This condition eliminates the sealing pressure necessary for effective air blocking. Replacement becomes necessary when compression exceeds 50 percent of original thickness.

Material degradation shows as cracking, hardening, or surface deterioration. UV exposure, temperature cycling, and chemical exposure contribute to material breakdown. Replace weather stripping showing significant degradation before complete failure occurs.

Adhesive failure manifests as sections pulling away from attachment surfaces. Temperature extremes and moisture exposure commonly cause adhesive breakdown. Mechanical fastening may provide temporary solutions, but replacement usually becomes necessary.

Energy Efficiency Benefits

Heating and Cooling Savings

Proper weather stripping can reduce heating and cooling costs by 10 to 20 percent in typical homes. These savings result from reduced air infiltration and improved HVAC system efficiency. The investment in quality weather stripping typically pays for itself within two years.

Air exchange rates decrease significantly with effective door sealing. Uncontrolled air infiltration forces heating and cooling systems to work harder maintaining desired temperatures. Reduced air exchange allows systems to operate more efficiently with longer cycles.

Comfort improvements extend beyond energy savings to include more consistent indoor temperatures. Drafty doors create cold spots and temperature variations that affect occupant comfort. Proper sealing eliminates these comfort issues while reducing energy consumption.

Indoor Air Quality Impact

Controlled ventilation becomes more effective when air infiltration is minimized. Mechanical ventilation systems can better manage indoor air quality when uncontrolled leaks are sealed. This control helps maintain proper humidity levels and air freshness.

Pollutant exclusion improves with effective door sealing systems. Outdoor pollutants, allergens, and dust enter homes through air leaks around doors. Quality weather stripping blocks these contaminants while allowing controlled ventilation.

Moisture control benefits from reduced air infiltration during humid conditions. Uncontrolled air exchange can introduce excess moisture that promotes mold growth and structural damage. Proper sealing helps maintain appropriate indoor humidity levels.

Common Installation Mistakes

Sizing Errors

Incorrect gap measurements lead to ineffective sealing or door operation problems. Gaps that are too small prevent proper door closing, while oversized gaps allow continued air leakage. Measure gaps carefully under normal operating conditions.

Compression calculations require understanding how much weather stripping will compress during door operation. Insufficient compression provides poor sealing, while excessive compression may prevent proper door closing. Follow manufacturer specifications for compression ratios.

Thermal expansion affects gap sizes throughout seasonal temperature changes. Materials expand and contract with temperature variations, affecting sealing effectiveness. Account for these changes when selecting weather stripping thickness and compression requirements.

Material Selection Problems

Climate mismatches occur when weather stripping materials aren’t suited for local conditions. Cold-climate installations require materials that remain flexible at low temperatures. Hot climates need UV-resistant materials that won’t degrade under intense sunlight.

Durability expectations should match actual door usage patterns. High-traffic doors require more durable materials than occasionally used entrances. Consider door operation frequency when selecting weather stripping materials and installation methods.

Compatibility issues arise when weather stripping materials react poorly with door or frame materials. Some adhesives may damage certain finishes or materials. Test compatibility in inconspicuous areas before full installation.

Installation Technique Issues

Surface preparation shortcuts commonly cause premature weather stripping failure. Inadequate cleaning or surface preparation prevents proper adhesive bonding. Take time to properly prepare all surfaces before installation begins.

Alignment problems create gaps in sealing coverage or interfere with door operation. Careful measurement and marking ensure proper weather stripping placement. Use temporary positioning methods to verify alignment before permanent attachment.

Fastener selection affects both holding power and appearance. Wrong fastener types may not provide adequate holding power or may damage weather stripping materials. Choose fasteners appropriate for both the weather stripping and attachment surface materials.

Professional vs. DIY Installation

Skill Requirements

Basic installations like foam tape application require minimal skills and common tools. Most homeowners can successfully complete these projects with careful attention to manufacturer instructions. Simple measuring and cutting skills are sufficient for basic weather stripping projects.

Advanced installations involving door modifications or complex gasket systems may require professional expertise. These projects often involve cutting grooves, adjusting door clearances, or modifying hardware. Professional installation ensures proper fit and long-term performance.

Tool requirements vary significantly between different weather stripping types. Basic installations need only measuring tools and utility knives. Complex installations may require specialized cutting tools, routers, or adjustment equipment not commonly available to homeowners.

Cost Considerations

Material costs represent a small portion of total project expenses for most weather stripping applications. Labor costs for professional installation often exceed material costs by significant margins. DIY installation can reduce total project costs by 60 to 80 percent.

Time investments for DIY projects include learning proper techniques and completing installation work. First-time installations typically take longer than expected as homeowners learn proper methods. Professional installers complete projects more quickly due to experience and specialized tools.

Quality outcomes depend on proper technique execution regardless of who performs the work. Professional installers bring experience and specialized knowledge that can improve results. However, careful DIY work following manufacturer instructions can achieve excellent results.

When to Call Professionals

Structural modifications like threshold replacement or door frame adjustments require professional expertise. These modifications affect door operation and home security when performed incorrectly. Professional installation ensures proper function and maintains structural integrity.

Complex door systems with multiple sealing points or integrated hardware benefit from professional installation. These systems require precise adjustment and specialized knowledge for optimal performance. Professional installers understand system interactions and adjustment procedures.

Warranty considerations may require professional installation for coverage validation. Some manufacturers void warranties when products are not installed by qualified professionals. Check warranty requirements before deciding between DIY and professional installation.

Frequently Asked Questions

How often should weather stripping be replaced?

Weather stripping replacement frequency depends on material type, climate conditions, and door usage patterns. Foam tape typically requires replacement every 2-3 years, while quality rubber gaskets may last 5-10 years.

High-traffic doors experience more wear and may need more frequent replacement. Exterior doors facing harsh weather conditions also require more frequent attention. Regular inspection helps determine actual replacement needs based on condition rather than arbitrary schedules.

Seasonal inspections help identify replacement needs before complete failure occurs. Check weather stripping condition during spring and fall maintenance periods. Address minor issues promptly to prevent progressive deterioration and maintain energy efficiency.

Can weather stripping be painted?

Painting weather stripping is generally not recommended as it can affect flexibility and sealing performance. Paint may crack when materials compress and expand during door operation. Most weather stripping materials are available in colors that complement common door finishes.

Specialized paints designed for flexible materials may work on some weather stripping types. However, painting typically voids manufacturer warranties and may reduce service life. Consider replacing weather stripping with appropriately colored materials instead of painting existing installations.

Alternative solutions include selecting weather stripping colors that blend with door finishes or using materials designed to accept paint. Some manufacturers offer paintable weather stripping specifically designed for this application.

What’s the best weather stripping for sliding doors?

Sliding door weather stripping requires materials that don’t interfere with door operation while providing effective sealing. Brush seals work well for the bottom track, while compression gaskets seal the sides and top effectively.

Track-mounted systems provide excellent sealing for sliding doors without affecting operation. These systems use specialized profiles that compress when doors close while allowing smooth sliding motion. Professional installation ensures proper alignment and adjustment.

Maintenance requirements for sliding door weather stripping include regular cleaning of tracks and sealing surfaces. Accumulated debris can prevent proper sealing and interfere with door operation. Keep tracks clean and lubricated for optimal performance.

How do I measure gaps for weather stripping?

Gap measurement techniques vary depending on location and door type. Use feeler gauges or thin strips of paper to measure actual gap dimensions. Measure gaps at multiple points as dimensions often vary along door perimeters.

Compression requirements must be considered when selecting weather stripping thickness. Most materials require 25-50% compression for effective sealing. Choose materials slightly thicker than measured gaps to ensure adequate compression when doors close.

Seasonal variations affect gap dimensions due to thermal expansion and humidity changes. Measure gaps during moderate weather conditions for most accurate sizing. Account for seasonal changes when selecting weather stripping materials and thickness.

Can weather stripping reduce noise?

Sound reduction is a secondary benefit of quality weather stripping installation. Sealing air gaps also blocks sound transmission pathways around doors. However, weather stripping alone cannot eliminate all noise transmission through door assemblies.

Acoustic performance improves most significantly for high-frequency sounds that travel through small gaps. Low-frequency sounds may still transmit through door materials themselves. Combining weather stripping with solid-core doors provides better overall sound control.

Installation quality affects both sealing and acoustic performance. Gaps in weather stripping coverage allow both air and sound transmission. Ensure continuous coverage around entire door perimeters for maximum noise reduction benefits.

Make Your Home More Comfortable Today

Transform your home’s comfort and efficiency with the right weather stripping solution. Quality materials and proper installation create lasting improvements that pay dividends for years. Your family deserves a comfortable, energy-efficient home that protects against the elements.

Don’t let another season pass with drafty doors costing you money and comfort. The solutions outlined in this guide provide proven results for homeowners nationwide. Take action today and start enjoying the benefits of professional-grade weather stripping.

Your investment in quality weather stripping represents one of the most cost-effective home improvements available. Start with the most problematic doors and expand your efforts as time and budget allow.