Best Automotive Paint Gun: Your Complete Guide to Professional Results

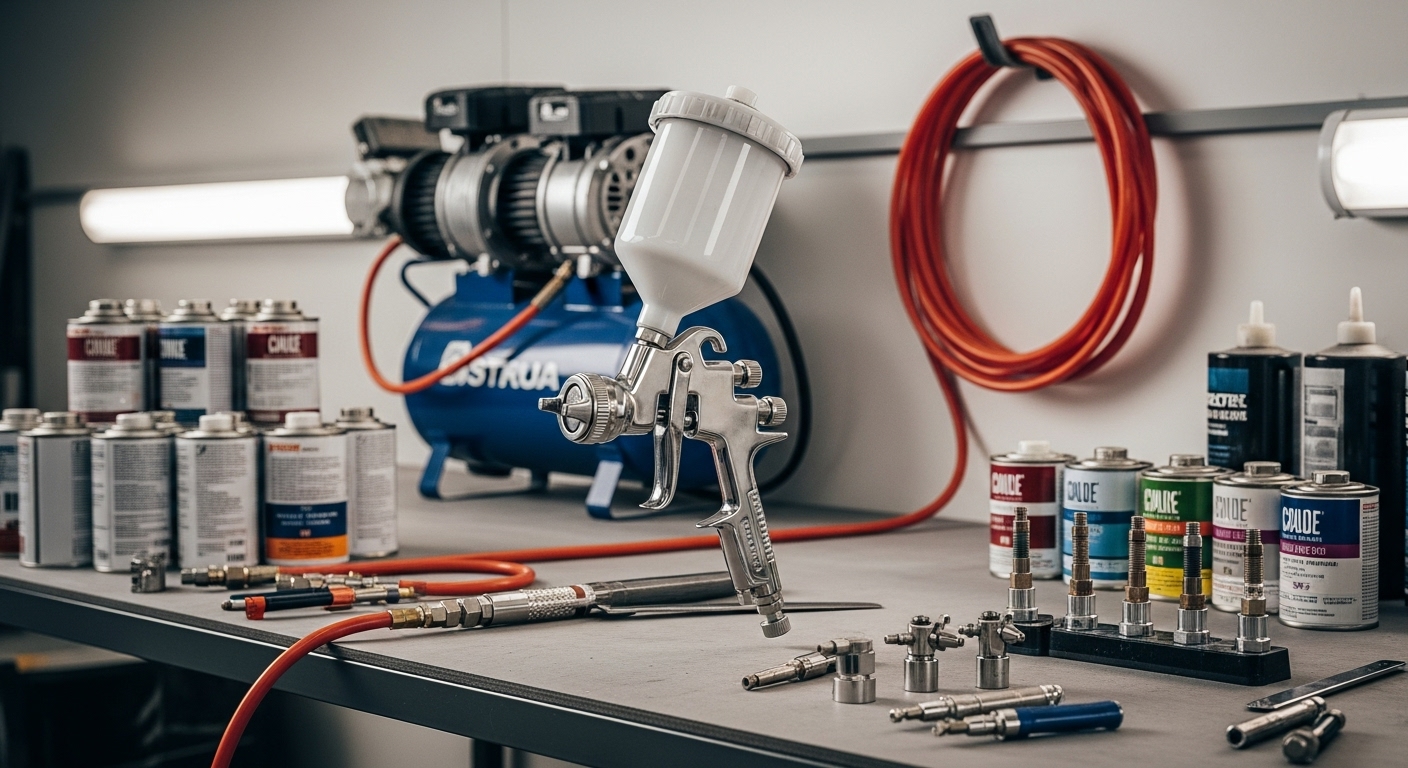

Transform your vehicle’s appearance with the right automotive paint gun. Whether you’re a professional painter or DIY enthusiast, choosing the perfect spray gun can make the difference between amateur results and showroom-quality finishes.

The best automotive paint guns combine precision control, consistent spray patterns, and durable construction to deliver flawless paint jobs every time. These tools offer superior atomization, reduced overspray, and professional-grade performance that elevates your painting projects.

This comprehensive guide reveals everything you need to know about selecting, using, and maintaining automotive paint guns. You’ll discover the key features that separate exceptional tools from mediocre ones, ensuring your investment delivers outstanding results for years.

Key Takeaways

- HVLP guns deliver superior results – High Volume Low Pressure technology provides the best transfer efficiency with minimal overspray, making them the gold standard for professional automotive painting.

- Spray pattern control is essential – Look for guns with adjustable horizontal, vertical, and round patterns to handle everything from large panels to detailed trim work with precision.

- Material compatibility matters significantly – Water-based paints require stainless steel components while solvent-based formulations need specific seals and gaskets to prevent damage and ensure longevity.

- Proper air pressure optimization is critical – Too little pressure creates orange peel texture while excessive pressure causes overspray and dry spray defects that ruin finish quality.

- Environmental conditions dramatically affect results – Ideal painting conditions are 70-75°F with 40-50% humidity, and proper dust control is essential for achieving showroom-quality finishes.

- Regular maintenance extends gun life – Daily cleaning after each use and periodic replacement of wear parts like needles and nozzles ensures consistent spray quality and prevents costly repairs.

- Practice and technique development are crucial – Maintaining consistent spray distance (6-8 inches), parallel gun movement, and 50-75% overlap patterns separates professional results from amateur attempts.

Automotive Paint Gun Types

HVLP Paint Guns

High Volume Low Pressure (HVLP) guns represent the gold standard for automotive painting. These tools use high air volume at low pressure to atomize paint efficiently. The result is superior transfer efficiency with minimal overspray.

HVLP guns excel at delivering smooth, even coats while conserving paint. They’re particularly effective for basecoats and clearcoats where precision matters most. The lower pressure reduces bounce-back, making them ideal for detailed work around curves and edges.

Professional painters favor HVLP systems because they meet environmental regulations while maintaining exceptional finish quality. The technology ensures more paint reaches the surface rather than floating away as waste.

LVLP Paint Guns

Low Volume Low Pressure (LVLP) guns offer a middle ground between traditional spray guns and HVLP systems. They require less air volume than HVLP guns while maintaining excellent atomization quality.

These guns work well with smaller compressors, making them popular among home enthusiasts. The reduced air consumption means you can achieve professional results without investing in massive air compressor systems.

LVLP guns provide consistent spray patterns and good transfer efficiency. They’re versatile enough for various paint types and viscosities, from primers to topcoats.

Conventional Paint Guns

Traditional high-pressure spray guns remain relevant for specific applications. They excel at spraying thick materials like primers and high-build coatings that require aggressive atomization.

These guns produce excellent penetration and coverage on textured surfaces. While they generate more overspray than modern alternatives, they’re unmatched for certain specialized applications.

Professional body shops often maintain conventional guns alongside newer technology for maximum versatility across different painting scenarios.

Key Features to Consider

Spray Pattern Control

Adjustable spray patterns are essential for automotive work. Look for guns offering horizontal, vertical, and round patterns. This versatility allows you to tackle everything from large panels to detailed trim work.

Pattern width adjustment lets you match the spray to your project size. Wide patterns cover large areas quickly, while narrow patterns provide precision for small components and touch-up work.

Quality guns feature smooth, consistent adjustments that maintain their settings throughout extended use. Cheap alternatives often drift or stick, compromising your finish quality.

Fluid Control Systems

Precise fluid control determines paint flow rate and coating thickness. Needle and nozzle combinations work together to regulate material delivery with exceptional accuracy.

Look for guns with easily replaceable needle and nozzle sets. Different sizes accommodate various paint viscosities and application requirements. Fine needles work best with thin materials, while larger setups handle thick primers and sealers.

The trigger mechanism should provide smooth, progressive control from initial paint release to full flow. Jerky or inconsistent triggers create uneven coatings and visible defects.

Air Cap Design

The air cap shapes the spray pattern and controls atomization quality. Precision-machined air caps ensure consistent performance and long service life.

Multiple air holes create the spray pattern while center holes provide atomizing air. The arrangement and size of these holes dramatically affect spray characteristics and finish quality.

Quality air caps resist clogging and maintain their geometry under regular cleaning. Cheap alternatives often distort or wear quickly, degrading spray quality over time.

Material Compatibility and Viscosity

Paint Types and Formulations

Modern automotive paints include water-based and solvent-based formulations, each requiring specific spray gun characteristics. Water-based paints need guns with stainless steel or specially coated fluid passages to prevent corrosion.

Solvent-based paints are more forgiving but still require proper gun selection. The aggressive solvents can attack certain seals and gaskets, making material compatibility crucial for long-term reliability.

Basecoat-clearcoat systems demand exceptional atomization quality. The basecoat provides color while the clearcoat delivers gloss and protection. Each layer requires different spray techniques and gun settings.

Viscosity Requirements

Paint viscosity affects spray gun performance dramatically. Thin materials flow easily but may run or sag if applied too heavily. Thick materials provide better coverage but require more aggressive atomization.

Most automotive paints require thinning for spray application. The reduction ratio depends on the paint type, gun specifications, and environmental conditions. Proper viscosity ensures optimal atomization and finish quality.

Viscosity cups help determine the correct consistency for your specific gun and paint combination. These simple tools eliminate guesswork and ensure consistent results across different batches and brands.

Primer and Sealer Applications

High-build primers require guns capable of handling thick, heavy materials. These products fill imperfections and provide a smooth base for color coats.

Sealers bridge the gap between primers and topcoats, ensuring proper adhesion and color uniformity. They typically spray at medium viscosity and require moderate atomization pressure.

Different primer types have varying spray characteristics. Epoxy primers flow differently than urethane or lacquer-based products, requiring specific gun setups for optimal results.

Setup and Calibration Techniques

Air Pressure Optimization

Proper air pressure is critical for achieving professional results. Too little pressure creates poor atomization and orange peel texture. Excessive pressure causes overspray and dry spray defects.

Start with manufacturer recommendations and adjust based on your specific conditions. Environmental factors like temperature and humidity affect optimal pressure settings.

Use a pressure gauge at the gun inlet to ensure accurate readings. Pressure drop through hoses and fittings can significantly reduce actual operating pressure compared to compressor settings.

Spray Distance and Technique

Consistent spray distance ensures uniform coating thickness and appearance. Most automotive applications require 6-8 inches between gun and surface for optimal results.

Maintain parallel gun movement across the surface. Arcing or tilting the gun creates uneven coating thickness and visible defects. Practice on test panels to develop smooth, consistent technique.

Overlap patterns should be 50-75% for most applications. This ensures complete coverage while avoiding heavy buildup in overlap areas. Consistent speed and spacing are essential for professional results.

Pattern Testing and Adjustment

Always test spray patterns on practice panels before starting actual work. Pattern quality reveals gun condition and setup accuracy immediately.

Look for even distribution across the entire pattern width. Heavy centers or weak edges indicate adjustment needs or worn components.

Document successful settings for different paint types and conditions. This reference information saves time and ensures consistent results across multiple projects.

Maintenance and Care

Daily Cleaning Procedures

Thorough cleaning after each use prevents paint buildup and component damage. Disassemble the gun according to manufacturer instructions and clean all fluid passages completely.

Use appropriate solvents for your paint type. Water-based paints require different cleaning agents than solvent-based materials. Never mix incompatible solvents or cleaners.

Lubricate moving parts with manufacturer-recommended oils or greases. Proper lubrication ensures smooth operation and extends component life significantly.

Component Replacement

Wear parts like needles, nozzles, and seals require periodic replacement. Monitor these components for wear patterns and replace them before they affect spray quality.

Keep spare parts inventory for critical components. Unexpected failures during important projects can be costly and frustrating without readily available replacements.

Quality replacement parts maintain gun performance and reliability. Generic or aftermarket parts may not meet original specifications and can compromise spray quality.

Storage and Protection

Proper storage protects your investment and ensures reliable performance. Clean guns thoroughly and apply protective coatings to prevent corrosion during extended storage periods.

Store guns in protective cases or dedicated storage areas. Dust and debris can contaminate internal components and affect spray quality when you return to work.

Climate-controlled storage prevents condensation and corrosion in humid environments. Temperature fluctuations can also affect seals and gaskets over time.

Professional Tips and Techniques

Environmental Considerations

Temperature and humidity dramatically affect paint application and curing. Ideal conditions are 70-75°F with 40-50% relative humidity for most automotive paints.

Air movement helps solvent evaporation but excessive drafts can cause dry spray and contamination. Balance ventilation needs with spray quality requirements.

Dust control is critical for high-quality finishes. Use tack cloths and air filtration systems to minimize contamination during application.

Advanced Spray Techniques

Wet-on-wet application requires precise timing and technique. Each coat must be applied within the recoat window to ensure proper adhesion and appearance.

Mist coats help achieve uniform color and eliminate mottling in metallic paints. These light applications require reduced fluid flow and careful technique.

Blending techniques seamlessly integrate repairs with existing paint. Gradual color transitions require exceptional gun control and spray pattern manipulation.

Troubleshooting Common Issues

Orange peel texture results from improper atomization or application technique. Adjust air pressure, spray distance, or material viscosity to correct this defect.

Dry spray appears as a rough, sandy texture caused by excessive air pressure or improper spray distance. Reduce pressure or move closer to the surface.

Runs and sags indicate excessive material application or improper viscosity. Reduce fluid flow or thin the material to prevent these defects.

Frequently Asked Questions

What makes HVLP guns better for automotive painting?

HVLP guns provide superior transfer efficiency by using high air volume at low pressure. This reduces overspray significantly while maintaining excellent atomization quality.

The lower pressure prevents paint bounce-back, ensuring more material reaches the surface. This efficiency saves paint costs and reduces environmental impact.

Professional results are easier to achieve with HVLP technology because the spray pattern remains consistent and controllable across various paint types.

How often should I replace spray gun components?

Needle and nozzle replacement depends on usage frequency and maintenance quality. Professional shops typically replace these components every 6-12 months with regular use.

Seals and gaskets may need replacement annually or when leakage occurs. Quality components last longer with proper cleaning and lubrication.

Monitor spray pattern quality as the best indicator of component condition. Deteriorating patterns signal the need for inspection and potential replacement.

Can I use the same gun for different paint types?

Thorough cleaning between different paint types is essential to prevent contamination and chemical reactions. Some combinations require complete disassembly and specialized cleaning procedures.

Dedicated guns for specific paint types eliminate cross-contamination risks and reduce cleaning time. Professional shops often maintain separate guns for primers, basecoats, and clearcoats.

Material compatibility varies between gun components and paint formulations. Check manufacturer recommendations before switching between significantly different materials.

What air compressor size do I need?

HVLP guns typically require 10-20 CFM at operating pressure. Your compressor should provide 1.5-2 times this capacity for consistent performance during extended use.

Tank size affects duty cycle more than peak performance. Larger tanks provide more consistent pressure during continuous spraying operations.

LVLP guns require less air volume, making them suitable for smaller compressors. This makes them popular choices for home workshops with limited air capacity.

How do I achieve professional-quality results?

Proper preparation accounts for 80% of finish quality. Clean, smooth surfaces are essential for professional appearance regardless of gun quality or technique.

Consistent technique develops through practice and attention to detail. Maintain steady speed, distance, and overlap patterns throughout the entire project.

Quality materials and proper mixing ratios ensure optimal performance. Never compromise on paint quality or mixing accuracy to save costs.

Your Path to Professional Automotive Painting Success

Investing in the best automotive paint gun transforms your painting capabilities and results quality. The right tool combines precision engineering with user-friendly operation, delivering consistent professional finishes that enhance any vehicle’s appearance.

Quality spray guns pay for themselves through improved efficiency, reduced material waste, and superior results. Whether you’re restoring classic cars or maintaining modern vehicles, the right equipment makes every project more successful and enjoyable.

Take action today and elevate your automotive painting to professional standards. Your vehicles deserve the flawless finishes that only quality equipment can deliver.